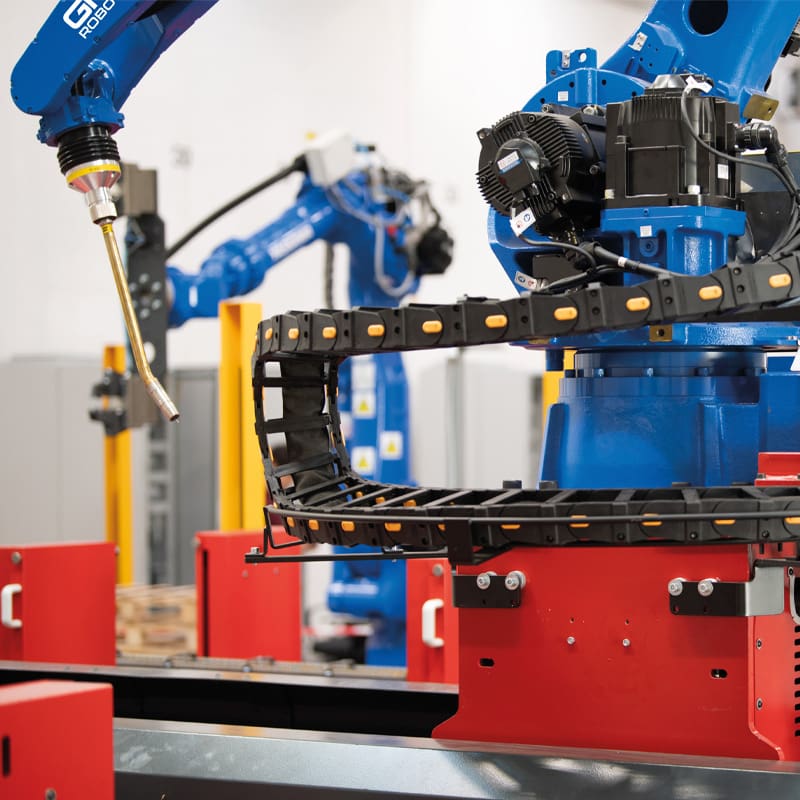

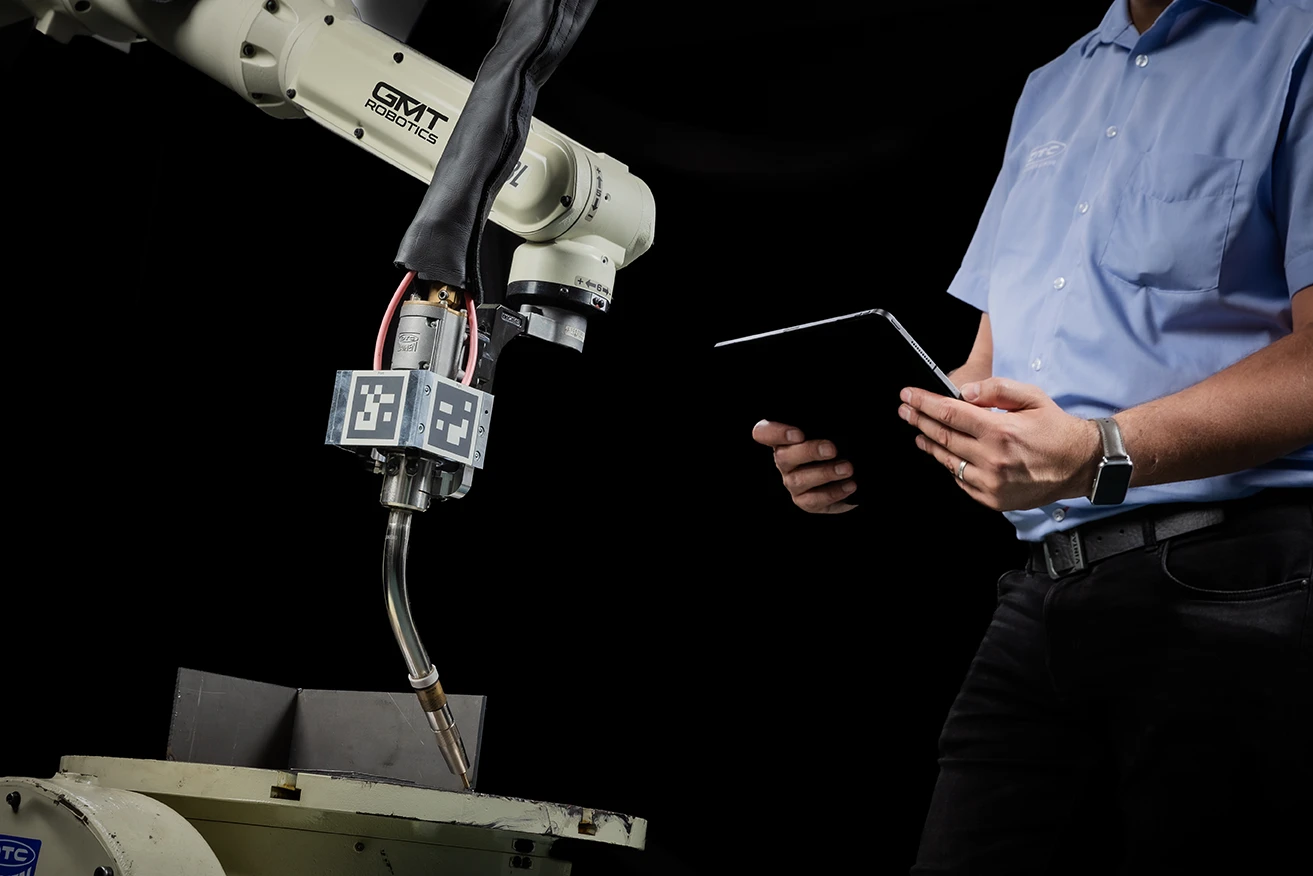

With the GMT Robotics MICRO ARCAS, you can triple the productivity of a single operator.

The MICRO ARCAS system enables the robot to handle welding on one side, while the operator loads the next cage on the opposite side.

MICRO ARCAS version 2.0 can accommodate cages from 150-450 mm in height, 100-400 mm in width, and up to 4.5m in length, with a weldable area of 2.5 m.

Additional lengths and dimensions are available upon request.

The ARCAS system is designed with safety at its core, significantly reducing workplace health risks and hazards.

By automating strenuous and hazardous welding tasks, it minimizes workers’ exposure to harmful fumes and repetitive strain injuries.

Additionally, the system allows for operation by unskilled personnel in a safe and controlled manner. Loading the system is straightforward and eliminates the risk of hand injuries, such as finger pinching, which commonly occur in manual handling. Traditionally, introducing longitudinal bars required multiple workers, increasing the likelihood of accidents.

With ARCAS, a single operator can efficiently perform this task with no risk of injury, streamlining production while maintaining the highest safety standards.

All our systems are CE approved.

Our user-friendly interface makes welding cages recipe simpler than ever. Operators can easily select the desired cage recipe and quantity on the screen, then press start - ensuring a seamless and efficient workflow.

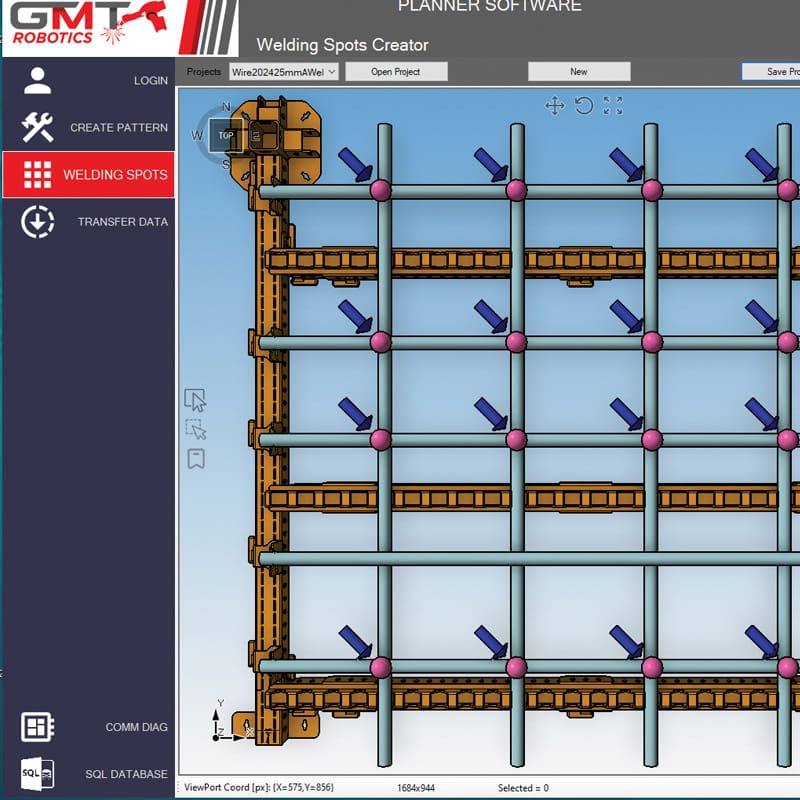

With the MICRO ARCAS, it’s even possible to produce two different cages simultaneously, maximizing productivity. For even greater efficiency, you can opt for our Planner Software, which allows you to import data and cage designs directly into the system.

With the GMT Robotics MICRO ARCAS, you can triple the productivity of a single operator.

The MICRO ARCAS system enables the robot to handle welding on one side, while the operator loads the next cage on the opposite side.

MICRO ARCAS version 2.0 can accommodate cages from 150-450 mm in height, 100-400 mm in width, and up to 4.5m in length, with a weldable area of 2.5 m.

Additional lengths and dimensions are available upon request.

The ARCAS system prioritizes safety, greatly reducing workplace risks and health hazards. By automating strenuous welding tasks, it limits exposure to fumes and repetitive strain injuries. Its simple, safe operation allows even unskilled personnel to work without risk of hand injuries common in manual handling.

Where multiple workers were once needed to load longitudinal bars, a single operator can now perform the task safely and efficiently.

All ARCAS systems are CE approved.

Our user-friendly interface makes welding cages recipe simpler than ever. Operators can easily select the desired cage recipe and quantity on the screen, then press start - ensuring a seamless and efficient workflow.

With the MICRO ARCAS, it’s even possible to produce two different cages simultaneously, maximizing productivity. For even greater efficiency, you can opt for our Planner Software, which allows you to import data and cage designs directly into the system.

GMT Robotics ApS

Priorparken 833

2605 Broendby

Denmark

VAT no. DK 41198478

Phone nr. +45 71 99 41 37

E-mail: contact@gmtrobotics.com

Developed by næmt.nu