The WELDMATE seamlessly integrates quality control into your daily production process.

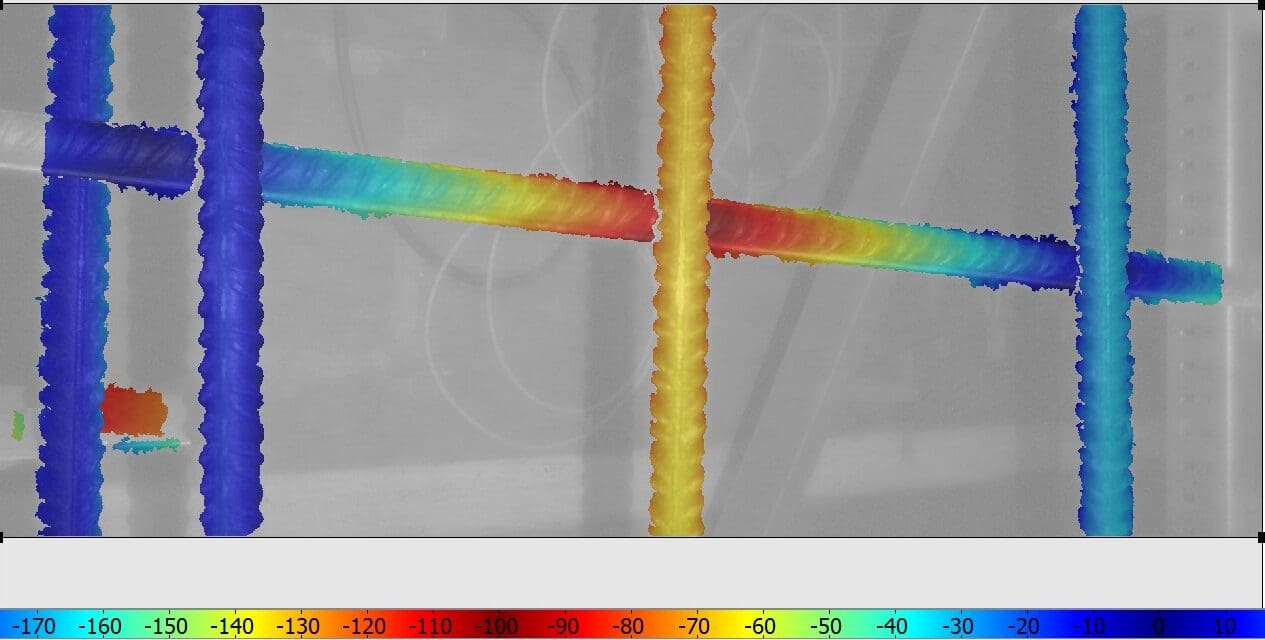

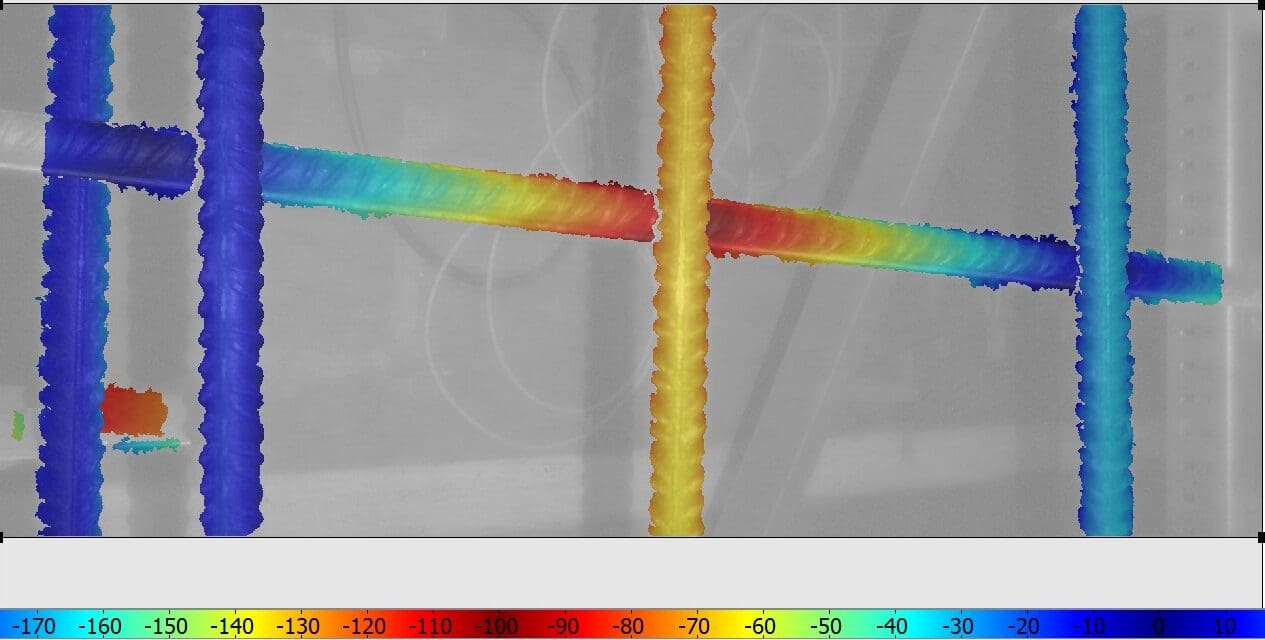

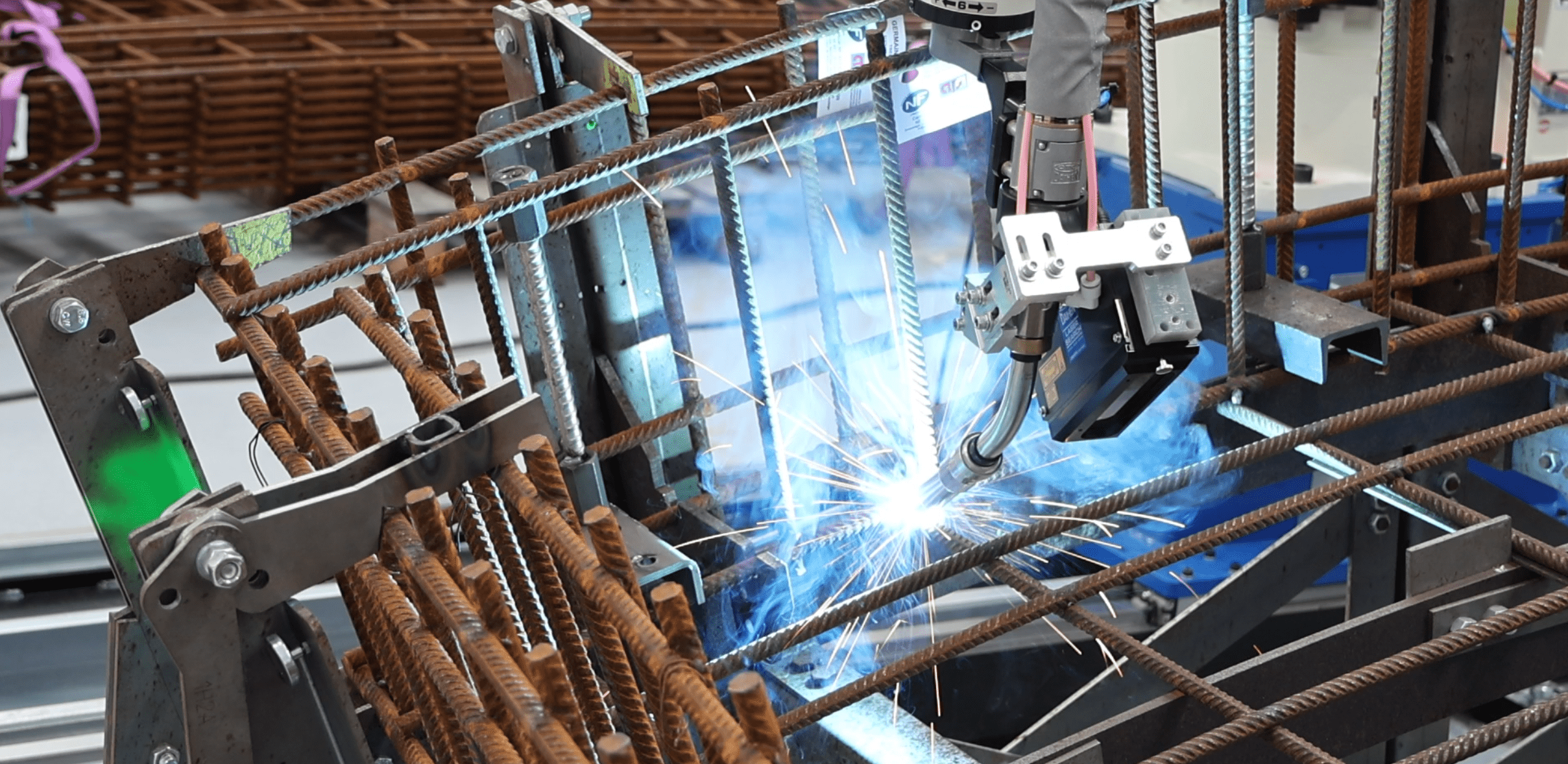

With 3D vision, it automatically identifies gaps between rebar and selects the most optimal welding recipe.

All data is automatically collected and compiled into a comprehensive report, serving as quality assurance for your end customer.

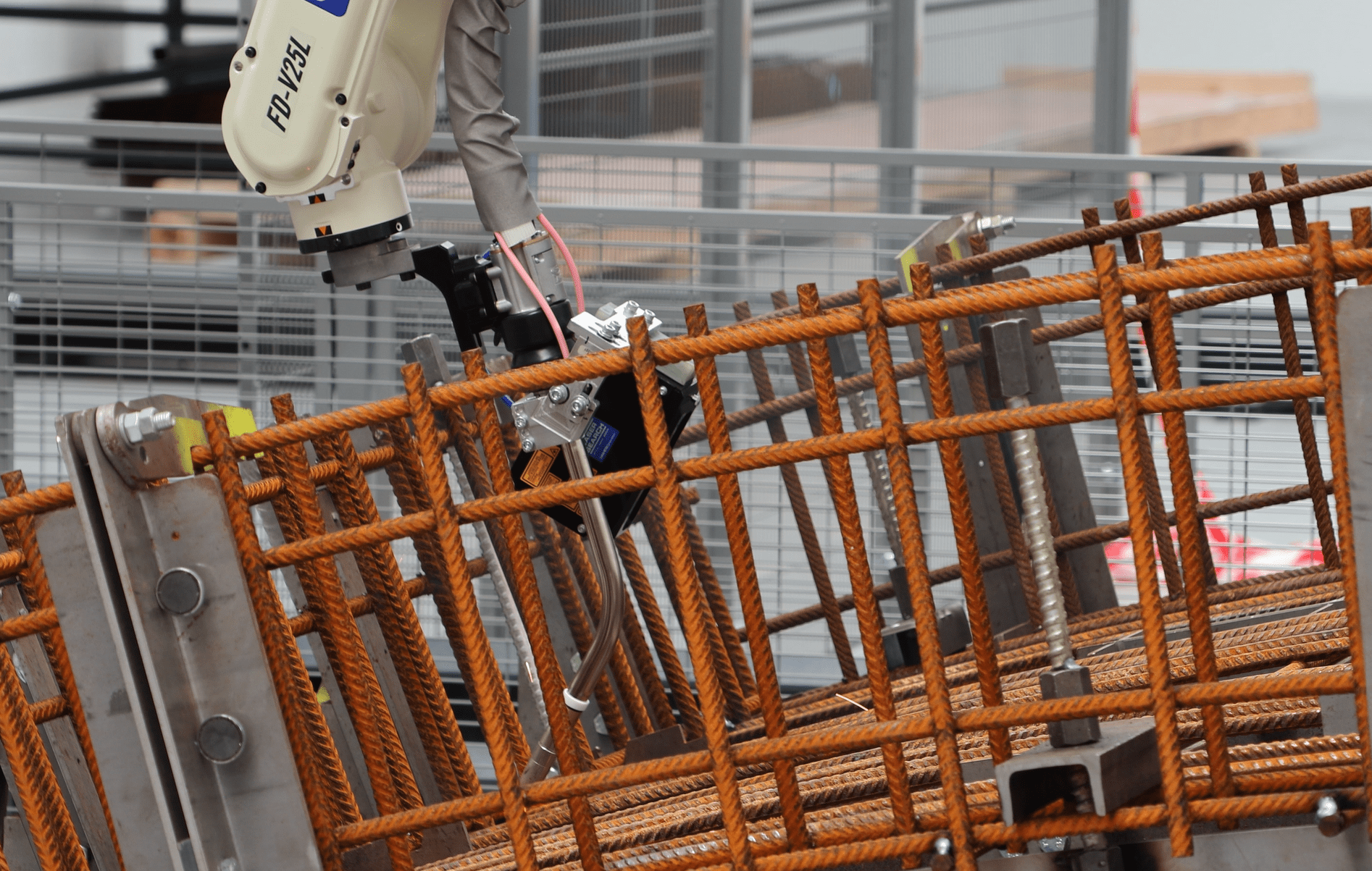

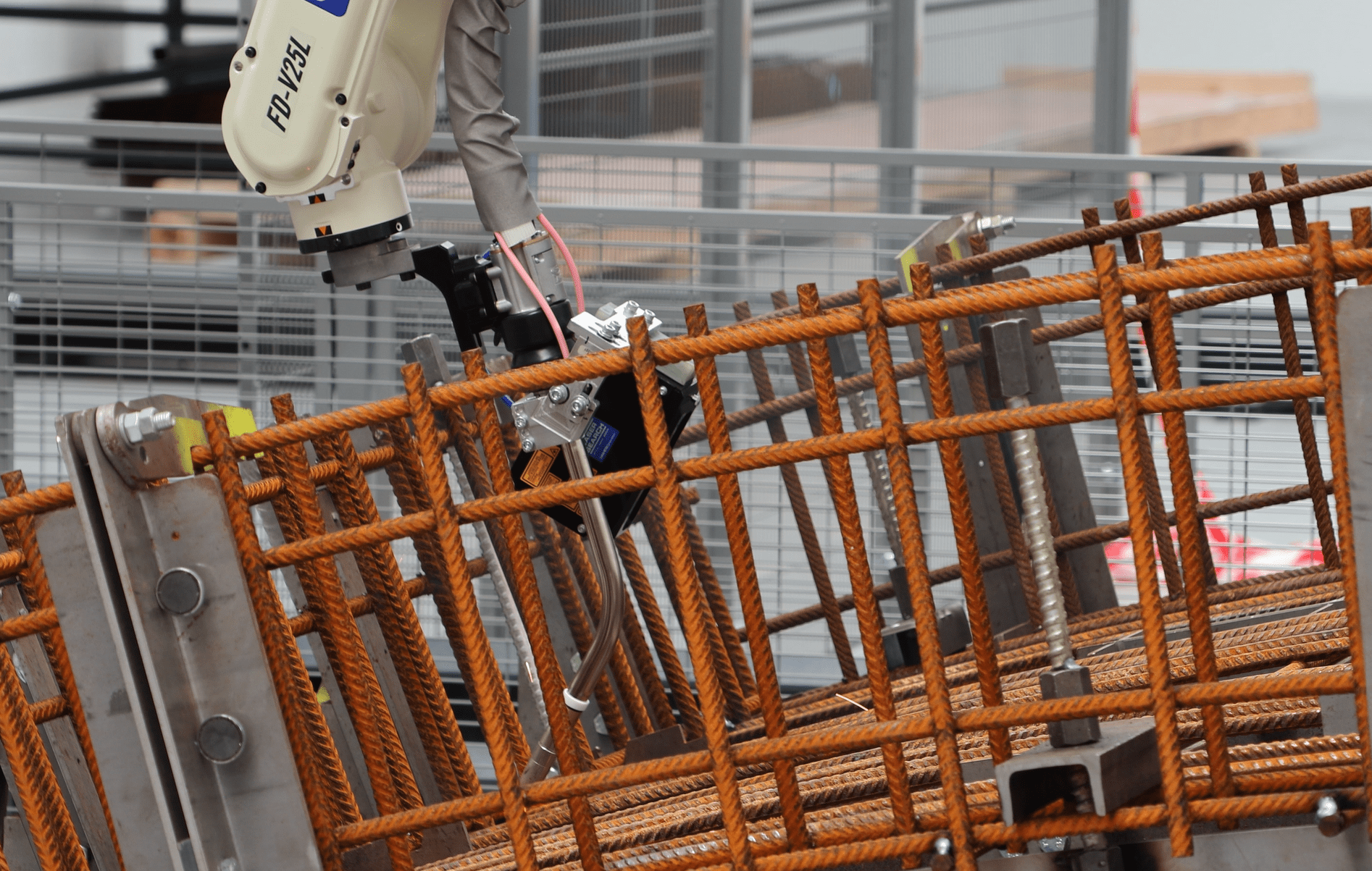

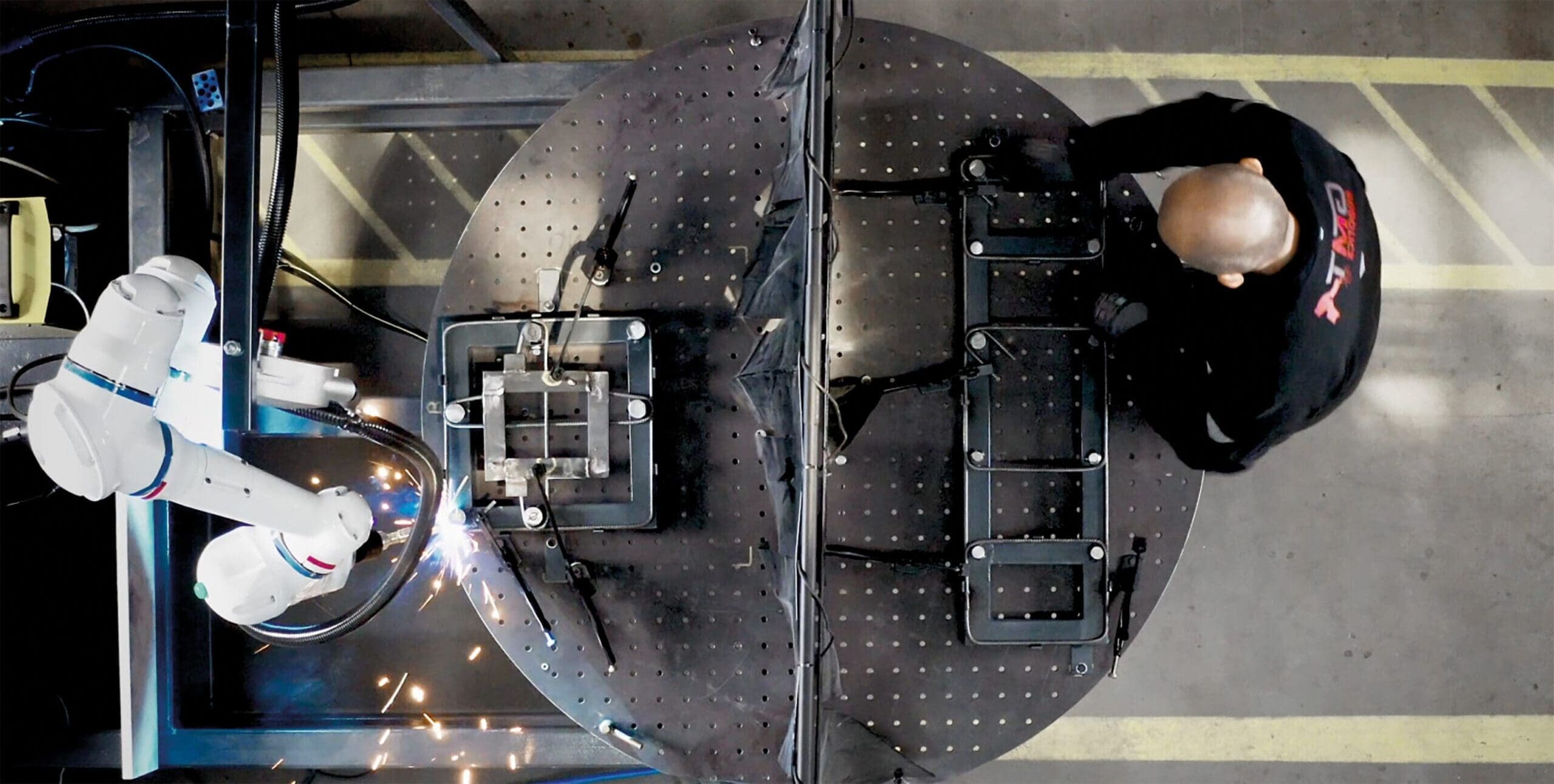

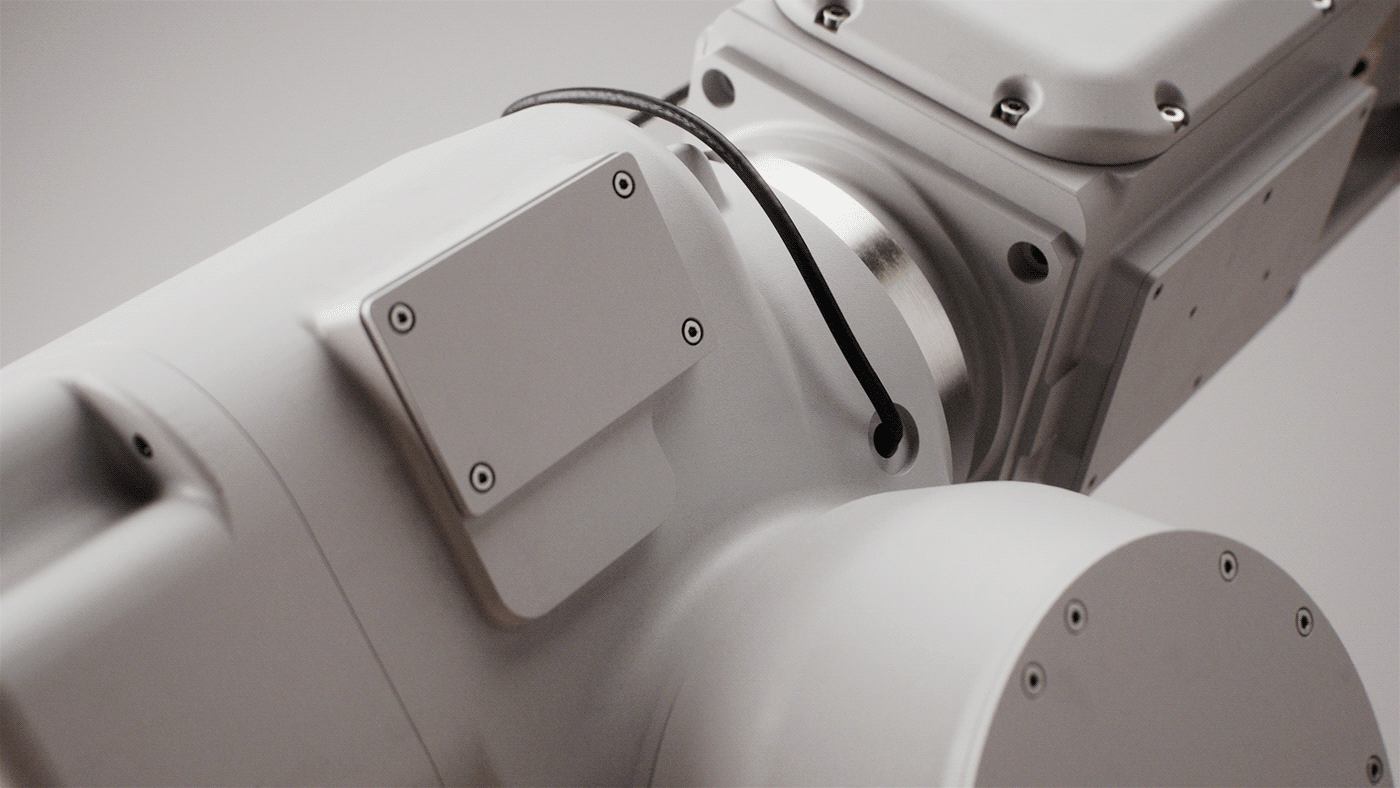

The WELDMATE system is designed for safe and efficient human-robot collaboration. In collaborative mode, it operates safely alongside workers at a controlled speed of 250mm/sec, eliminating the need for safety fencing.

For increased productivity, the robot can switch to industrial mode, reaching speeds of 1.2m/sec. When equipped with the appropriate safety system, it can operate at speeds of up to 4m/sec, significantly outperforming standard collaborative robots while maintaining strict safety standards.

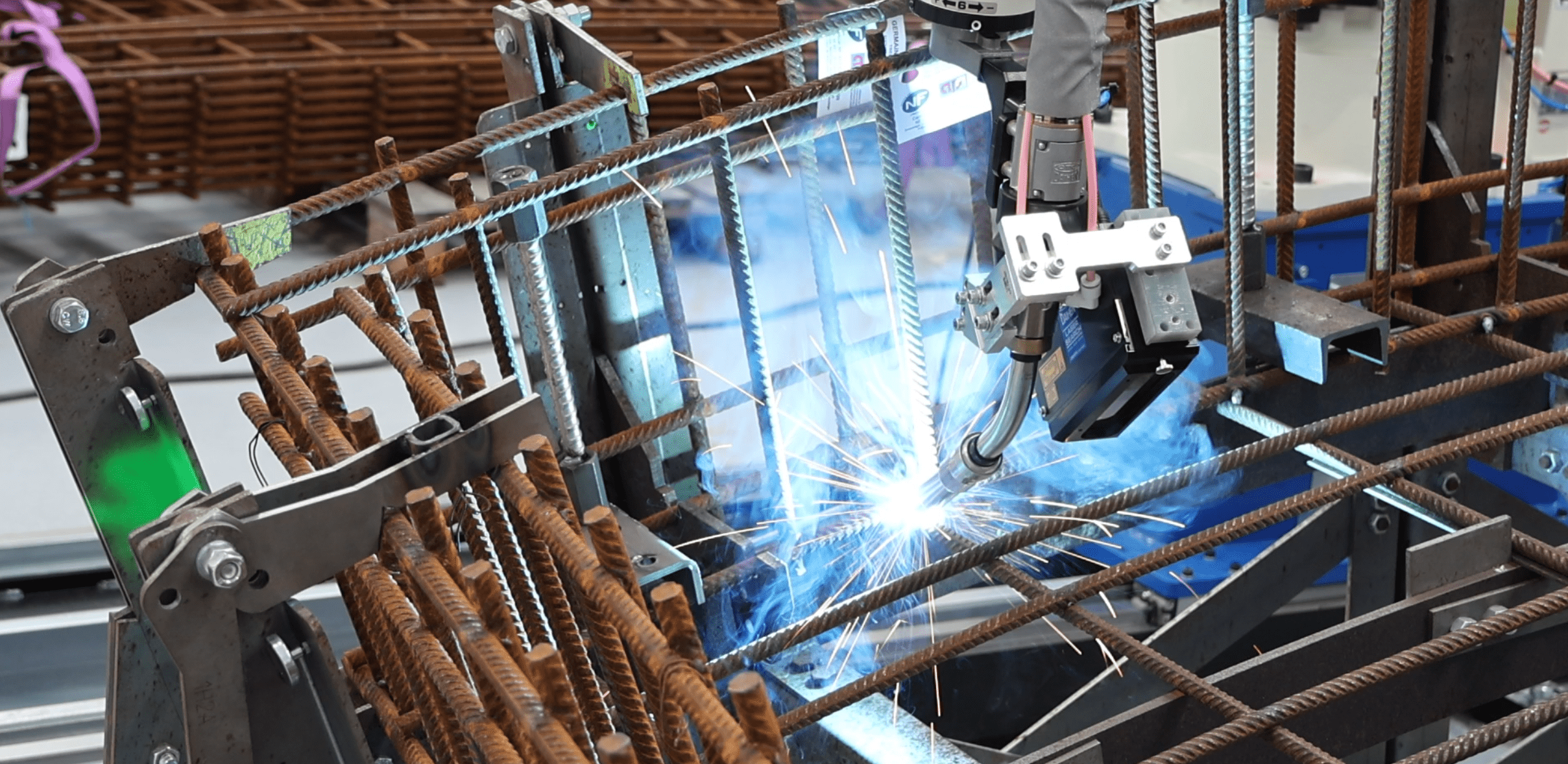

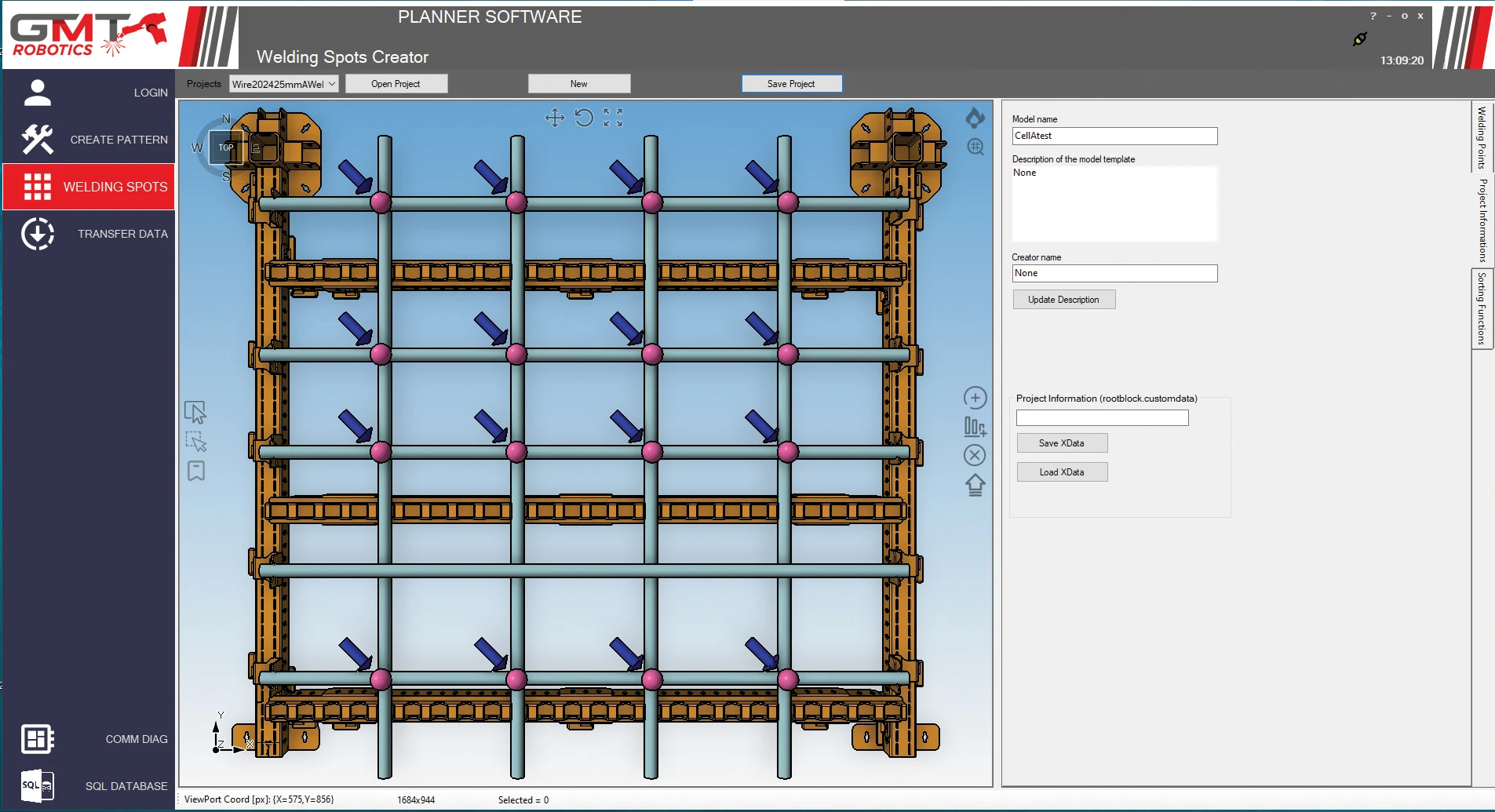

As a standard feature, both the WELDMATE and MEGA WELDMATE are equipped with advanced Search & Detect technology. Seamlessly integrated into our hardware and software, this system allows the robot to automatically identify the precise welding point at any

intersection - whether in a link, cage, or mesh.

By intelligently compensating for jig inaccuracies, the robot not only ensures precision but also selects and loads the correct welding recipe automatically. This results in a seamless, efficient welding process with minimal manual intervention.

The WELDMATE seamlessly integrates quality control into your daily production process.

With 3D vision, it automatically identifies gaps between rebar and selects the most optimal welding recipe.

All data is automatically collected and compiled into a comprehensive report, serving as quality assurance for your end customer.

The WELDMATE system is designed for safe and efficient human-robot collaboration. In collaborative mode, it operates safely alongside workers at a controlled speed of 250mm/sec, eliminating the need for safety fencing.

For increased productivity, the robot can switch to industrial mode, reaching speeds of 1.2m/sec. When equipped with the appropriate safety system, it can operate at speeds of up to 4m/sec, significantly outperforming standard collaborative robots while maintaining strict safety standards.

As a standard feature, both the WELDMATE and MEGA WELDMATE are equipped with advanced Search & Detect technology. Seamlessly integrated into our hardware and software, this system allows the robot to automatically identify the precise welding point at any

intersection - whether in a link, cage, or mesh.

By intelligently compensating for jig inaccuracies, the robot not only ensures precision but also selects and loads the correct welding recipe automatically. This results in a seamless, efficient welding process with minimal manual intervention.

GMT Robotics ApS

Priorparken 833

2605 Broendby

Denmark

VAT no. DK 41198478

Phone nr. +45 71 99 41 37

E-mail: contact@gmtrobotics.com

Developed by næmt.nu